Орчин үеийн үйлдвэрлэлд чөлөөлөх бодисын хувьсгалт нөлөөг ойлгох

Үйлдвэрлэлийн салбар нь үйлдвэрлэлийн үр ашгийг болон бүтээгдэхүүний чанарыг сайжруулах шинэ шийдлүүдийг оруулж тасралтгүй хөгжиж байна. Эдгээр шинэчлэлүүдийн дотор тосон суналцтай нь олон төрлийн үйлдвэрлэлийн процессоор чухал өөрчлөлтийг авчирсан бүрэлдэхүүн хэсэг болон гарч ирсэн. Энэ нарийн боловсруулсан найрлага нь хэлбэрээс салгах ажиллагааг үйлдвэрлэгчид яаж хандаж буйг өөрчилсөн бөгөөд үйлдвэрлэлийн үр дүнг илүү сайжруулж, үйл ажиллагааны бэрхшээлийг багасгасан.

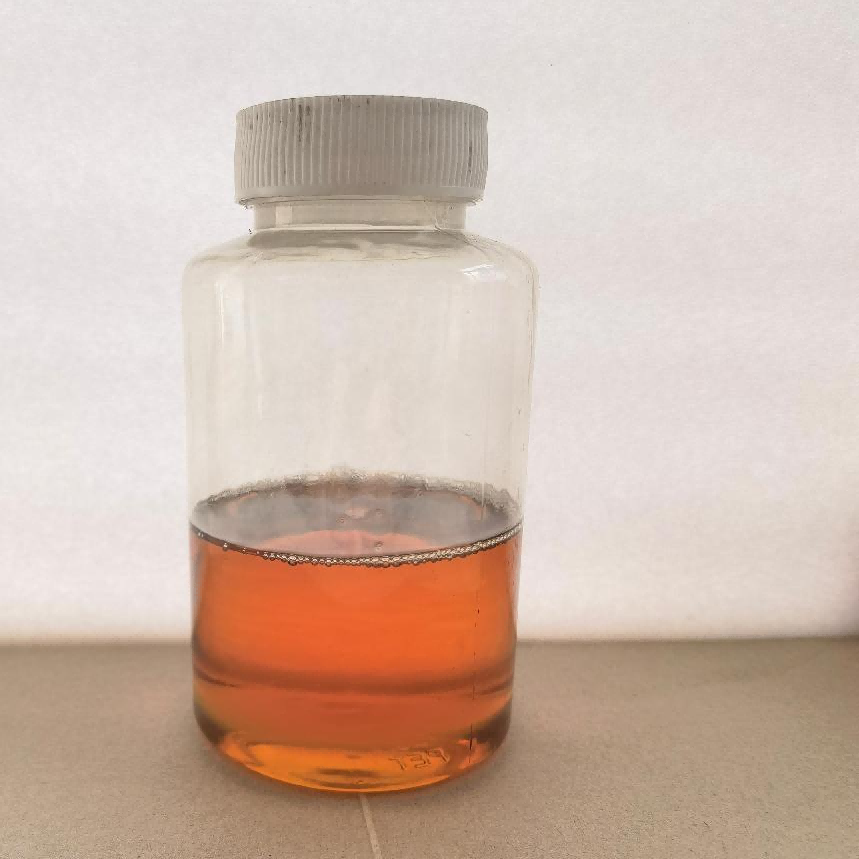

Өнөөгийн өрсөлдөөнт үйлдвэрлэлийн орчинд салгалтын агентийн сонголт нь дунд зэргийн болон онцгой үр дүнгийн хоорондох ялгааг тодорхойлдог. Тосон суурьтай тусгаарлагч бодис бетон хэлбэрлэхээс хүртэл пластик хэлбэрлэх хүртэлх өөр өөр хэрэглээнд тэд өөрсдийн үнэ цэнийг баталж, өөр шийдлүүдээс ялгарах давуу талын гүйцэтгэлийн шинж чанарыг санал болгодог.

Чухал шинж чанар ба онцлог

Химийн найрлага болон тогтвортой байдал

Нийлэг шингэнт тосон чөлөөлөх бодисын найрлага нь тусгай сонгосон суурин тосонд тусгай нэмэлтүүдийг нэмснээр бүрддэг. Эдгээр бүрэлдэхүүн хэсгүүд хамтын ажиллаж, тогтвортой, удаан үйлчилгээтэй чөлөөлөх нөлөөг үүсгэдэг. Эдгээр бодисын молекулын бүтэц нь онцгой дулааны тогтвортой чанартай бөгөөд өндөр температуртай нөхцөлд боловсруулах үед ч өөрчлөлтгүй үйлчлэх чадварыг хадгалдаг.

Ялгаатай химийн шинж чанар нь үйлдвэрлэлийн мөчлөгийн туршид тогтмол ажиллагааг хангаж, дахин олон удаа түрхэх шаардлагыг багасгаж, үйлдвэрлэлийн зогсолтыг хамгийн бага болгодог. Энэхүү тогтвортой байдал нь шууд үйл ажиллагааны үр ашгийг сайжруулж, материал хаягдалыг бууруулдаг.

Гадаргуугийн харилцан үйлчлэлийн механик

Мазутлаг шингэний чөлөөлөх бодис болон ороомгийн гадаргуу молекул түвшинд харилцан үйлчлэж, наалдахыг саатуулах, гадаргуугийн чанарыг хадгалах зориулалттай тохиромжтой заагийн давхаргыг үүсгэдэг. Энэ нарийн нийлмэл харилцан үйлчлэл нь эцсийн бүтээгдэхүүний гадаад дүр төрх, бүтцийн бүрэн байдлыг алдагдуулахгүйгээр цэвэрхэн салгах боломжийг бүрдүүлдэг.

Энэ бодис гадаргуугийн бус жигд байдлыг тохируулан микроскопын түвшинд саармагчлах давхаргыг үүсгэж, нарийн овоорхог ороомгийн геометр дүрсийн хувьд ч бүрэн хамрах чадвартай. Энэ олон талт чадвар нь нарийн дэлгэрэнгүй дүрсийг итгэл үнэмшилтэй дүрслэхийг шаарддаг үйлдвэрлэлийн процессуудад түүнийг онцгой ач холбогдолтой болгодог.

Үйлдвэрлэлийн давуу тал ба үр ашгийн нэмэгдэл

Бүтээгдэхүүний чанарыг сайжруулах

Үйлдвэрлэлийн гавьяа нь тогтмол чанартай гаралт шаарддаг бөгөөд мазутлаг шингэний чөлөөлөх бодис энэ зорилгийг хангахад төвийн үүрэг гүйцэтгэдэг. Ийнхүү эдгээр бодисын нэг төрлийн хэрэглээ, найдвартай үйлчилгээ нь гадаргуугийн дээд зэргийн чанар, бүтээгдэхүүний дутагдал багасах, хэмжээний нарийвчлалыг сайжруулахад хувь нэмрээ оруулдаг.

Чанарын хяналтын нарийн үзүүлэлтүүд нь зохистой шингэн тосны суурь дээр үндэслэсэн хиймэлчлэгчид ажиллагааг хэрэгжүүлснээр ихэвчлэн илүү сайжрах бөгөөд зарим үйлдвэрлэгчид бүтээгдэхүүний дутагдал багасах хувийг 40%-иар хүртэл гэж тайлагнадаг. Энэ сайжруулалт нь хаягдах материал багсаж, хэрэглэгчийн буцаалт цөөрөх замаар шууд ашгийг нэмэгдүүлдэг.

Ажиллагааны үнэ цэнэтэй оптимизаци

Анхдагч хөрөнгө оруулалт нь бусад сонголтуудтай харьцуулахад илүү өндөр байж магадгүй ч, өндөр чанартай шингэн тосны суурь дээр үндэслэсэн тусгалын агент нь урт хугацаанд эдийн засгийн үр дүнд тодорхой нөлөө үзүүлдэг. Тухайлбал, формны амьдралын хугацаа уртсаж, цэвэрлэх шаардлага багасаж, үйлдвэрлэлийн үр ашгаа сайжруулдаг. Гэхдээ илүү сайн хамрах болон тэсвэрт чанар нь нэг удаагийн хэрэглээнд цөөн хэмжээний тусгалын агент шаардлагатай болгох ба хэрэглээг бууруулдаг.

Үйлдвэрлэлийн газрууд өндөр чанартай шингэн тосны суурь дээр үндэслэсэн тусгалын агентаас өөрчлөлт хийснээс хойш техникийн хэвийн ажиллагааны зардал болон үйлдвэрлэлийн зогсонги байдлын хэмнэлтийг том хэмжээгээр бичиж авсан байдаг. Эдгээр хэмнэлтүүд цаг хугацаатай нэгдэж, ашиг орлогыг нэмэгдүүлэх, өрсөлдөх чадварыг дээшлүүлэхэд хувь нэмрээ оруулдаг.

Орчин үеийн тухай, хамгаалалтын талаар

Тогтвортой үйлдвэрлэлийн арга

Орчин үеийн тосон суулгах бодисын найрлагыг орчныг хамгаалах зорилгоор зохион бүтээдэг. Үйлдвэрлэгчид одоо өндөр үйлчилгээнийг хадгалж, орчныг бохирдуулах нөлөөг багасгадаг задран задрах чадвартай хувилбаруудыг санал болгодог. Эдгээр эко-найрлага нь компанийг бүтээгдэхүүн үйлдвэрлэх стандартыг хадгалах зэрэгцээ орчныг хамгаалах хатуу шаардлагуудыг хангахад тусалдаг.

Чанартай тосон суулгах бодисын хэрэглээ багасаж, үйлчилгээний хугацаа уртсанаар хаягдал багасах зорилготой уялддаг бөгөөд туршлагатай үйлдвэрлэлийн инициативтай нийцдэг. Энэ орчныг хамгаалах татах шинж чанар нь технологийн материал сонгоход үйлдвэрлэгчдийн хувьд чухал хүчин зүйл болсон.

Ажлын байрын аюулгүй байдлыг сайжруулах

Үйлдвэрлэх орчинд аюулгүй байдлын асуудлууд нь бага VOC (нийлмэл органик нэгдэл) агуулсан тосон суулгах бодисын найрлагыг хөгжүүлэхэд хүргэсэн. Эдгээр дэвшилтэт бҮТЭЭГДЭХҮҮН ажилчдын хортой бодисын нөлөөнд өртөхийг хамгийн бага болгох, харин шаардлагатай чанарын шинж чанарыг хадгалах. Аюулгүй ажлын байрын илүү сайн түвшин нь мэргэжлийн эрүүл мэндийн дүрэм журамд нийцэхийг дэмжиж, илүү сайн ажлын орчин бүрдүүлдэг.

Ажлын байранд агаарын чанарыг хянах, туршилт шалгалт хийх явцад модерн тосон гаралтай тусгаарлагч нь уламжлалт хувилбартай харьцуулахад илүү аюулгүй ажлын нөхцлийг бий болгодог байна. Энэ аспект нь үйлдвэрлэгчид ажилтны сайн сайхан байдлыг баталгаажуулах, хууль эрх зүйн шаардлагад нийцэхэд илүү ихээр анхаарч байгаа тул чухал болсон.

Түрхэх аргачлал ба шилдэг жишээнүүд

Оновчтой хэрэглэх аргууд

Тосон гаралтай тусгаарлагчийг амжилттай хэрэглэхийн тулд давуу талыг хамгийн их байлгах зорилгоор зөв хэрэглэх арга техникийг мөрдөх шаардлагатай. Спрей болон автоматжуулсан систем нь хэвийн хэмжээтэй үйлдвэрлэлд хамрах хүрээ, зузаан, нийтлэгийн нарийвчлалыг хангаж, операторуудыг зөв арга техникээр сургаснаар хамгийн тохиромжтой үр дүнг гаргах боломжийг олгодог.

Хэрэглэх температур, даралт болон хамрах хүрээ нь ашиг шимийг сайжруулахад чухал үүрэг гүйцэтгэнэ. Зөв сургалт болон хэрэгсэлд хөрөнгө оруулдаг үйлдвэрлэгчид ихэвчлэн үйлдвэрлэлийн үзүүлэлтэд илт сайжрал гаргадаг.

Засвар, хадгалалтын арга журмууд

Нийлэгт суурилсан тусгаарлагчийг зөв хадгалах, ашиглах нь үйлчилгээний үр дүнтэй байдлыг хадгалах, хугацааг нэмэгдүүлэхэд тусална. Температурыг хянах хадгалалтын байр, савыг сайн таглах, бохирдлоос сэргийлэх арга хэмжээ нь материал удирдах үндсэн хэсгүүд юм.

Хэрэглэх тоног төхөөрөмжийн байнгын засвар, системтэй цэвэрлэх арга хэмжээнүүд нь үйлчилгээний сайн ажиллагааг хадгалах, үйлдвэрлэлийн чанарыг муутгаж болох асуудлуудаас сэргийлэхэд тусална. Хандлагын болон засварын тодорхой арга журмыг боловсруулах нь үйлдвэрлэлийн үйл ажиллагааны тогтвортой үр дүнг хангана.

Ихэнх асуултууд

Үйлдвэрлэлийн явцад нийлэгт суурилсан тусгаарлагчийг хэдий нэг удаа хэрэглэх ёстой вэ?

Хэрэглэх давтамж нь үйлдвэрлэлийн хэмжээ, ажиллаж буй нөхцөл, тодорхой үйлдвэрлэлийн шаардлагууд зэрэг олон хүчин зүйлсээс хамаарна. Ерөнхийдөө чанартай тосон тусгаарлагч нэг удаагийн хэрэглээнд дахин хэрэглэх шаардлагагүйгээр олон удаа тусгаарлах чадвартай байдаг ч яг аль хугацаанд дахин хэрэглэхийг технологийн баталгаажуулалт болон хяналтаар тогтоох ёстой.

Тосон суурьтай тусгаарлагч нь усанд суурилсан тусгаарлагчид яагаад илүү дээдийг гаргах вэ?

Ерөнхийдөө тосон суурьтай тусгаарлагч нь усанд суурилсан хувилбараас илүү дулааны тогтвортой байдал, илүү урт хугацааны үйлчилгээ, илүү сайн тусгаарлагч чанартай байдаг. Эдгээр нь өндөр температуртай нөхцөлд илүү тогтвортой үр дүн өгдөг бөгөөд ихэвчлэн цөөн удаа хэрэглэдэг тул үйлдвэрлэлийн үр ашгийг сайжруулж, зардлыг бууруулдаг.

Тосон суурьтай тусгаарлагч эцсийн бүтээгдэхүүний гадаргуугийн төгсгөлд нөлөөлөх үү?

Зөв сонгож, зөв ашиглавал тосон чийдэх эрдэнэ нь цэвэр чийдэх боломжийг олгох, дутагдал үүсэхээс сэргийлж гадаргуугийн чанарыг сайжруулдаг. Чухал зүйл бол таны тодорхой хэрэглээнд тохирсон бүрэлдэхүүнийг сонгох ба үр дүнг хамгийн сайн байлгахын тулд зөвлөгдсөн ашиглах аргачлалыг дагах явдал юм.