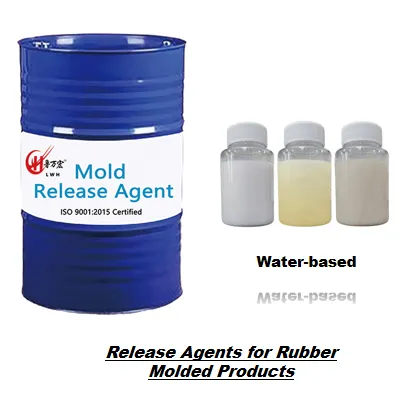

Innovation and Excellence in Industrial Release Solutions

In the ever-evolving landscape of industrial manufacturing, the choice of release agents plays a pivotal role in production efficiency and product quality. Luwanhong release agent has emerged as a game-changing solution, setting new industry standards through its innovative formulation and exceptional performance characteristics. This comprehensive exploration delves into the distinctive features that position Luwanhong release agent as a leader in manufacturing applications.

Superior Technical Advantages of Modern Release Agents

Advanced Chemical Composition

The foundation of Luwanhong release agent's superiority lies in its meticulously engineered chemical composition. Through years of research and development, the formulation has been perfected to achieve optimal release properties while maintaining environmental responsibility. The unique blend of high-grade polymers and specialized additives ensures consistent performance across various manufacturing conditions.

Unlike conventional release agents, the Luwanhong release agent incorporates cutting-edge molecular technology that creates an ultra-thin, uniform release film. This microscopic layer provides excellent separation between the mold and the finished product, significantly reducing the risk of defects and improving overall product quality.

Enhanced Performance Characteristics

The performance metrics of Luwanhong release agent demonstrate remarkable advantages in multiple areas. Its rapid curing time accelerates production cycles while maintaining superior release properties throughout extended manufacturing runs. The agent's thermal stability ensures reliable performance even under extreme temperature conditions, making it suitable for diverse industrial applications.

Furthermore, the product's exceptional durability translates to fewer applications needed per production cycle, resulting in reduced consumption and improved cost-efficiency. This longevity factor has made Luwanhong release agent particularly appealing to high-volume manufacturing operations seeking to optimize their production processes.

Environmental and Safety Considerations

Eco-friendly Formulation

In response to growing environmental concerns, Luwanhong release agent has been developed with sustainability in mind. The formulation contains minimal volatile organic compounds (VOCs) and is free from harmful substances commonly found in traditional release agents. This environmental consciousness extends throughout the entire product lifecycle, from manufacturing to application and disposal.

The biodegradable components used in Luwanhong release agent align with global environmental regulations while maintaining superior performance characteristics. This balance between ecological responsibility and industrial efficiency represents a significant advancement in release agent technology.

Workplace Safety Standards

Safety considerations have been paramount in the development of Luwanhong release agent. The product features low odor emission and reduced respiratory risks, creating a safer working environment for operators. Advanced filtration technology in the manufacturing process ensures consistent product purity and minimizes potential workplace hazards.

The implementation of strict quality control measures throughout production guarantees that each batch of Luwanhong release agent meets rigorous safety standards. This commitment to workplace safety has earned the trust of manufacturing facilities worldwide.

Versatility Across Manufacturing Sectors

Wide Application Range

The versatility of Luwanhong release agent extends across numerous manufacturing sectors, from automotive components to construction materials. Its adaptability to different substrate materials and processing conditions makes it an ideal solution for diverse industrial applications. The agent's performance remains consistent whether used in injection molding, compression molding, or other manufacturing processes.

This broad applicability reduces the need for multiple release agent variants in manufacturing facilities, simplifying inventory management and operational procedures. The ability to maintain high performance across various applications has made Luwanhong release agent a preferred choice for manufacturers seeking to streamline their operations.

Process Optimization Benefits

Implementation of Luwanhong release agent often leads to significant improvements in manufacturing efficiency. The product's quick release properties and minimal build-up characteristics reduce cleaning and maintenance requirements, leading to longer production runs and decreased downtime. These operational benefits translate directly to improved productivity and cost savings.

The consistent performance of Luwanhong release agent also contributes to higher first-pass yield rates, reducing waste and rework requirements. This reliability factor has proven particularly valuable in high-precision manufacturing environments where quality standards are exceptionally demanding.

Cost-Effectiveness and Return on Investment

Economic Advantages

While the initial investment in Luwanhong release agent may be higher than conventional alternatives, the long-term economic benefits are substantial. The reduced consumption rate, extended mold life, and decreased maintenance requirements contribute to significant cost savings over time. Manufacturing facilities have reported notable reductions in their overall operational expenses after switching to Luwanhong release agent.

The improved product quality and reduced reject rates further enhance the economic value proposition. These factors, combined with increased production efficiency, demonstrate the strong return on investment that Luwanhong release agent provides to manufacturing operations.

Long-term Value Proposition

The durability and consistency of Luwanhong release agent contribute to its long-term value proposition. The product's ability to maintain optimal performance characteristics over extended periods reduces the frequency of reapplication and minimizes production interruptions. This reliability factor is particularly valuable in continuous manufacturing operations where downtime costs can be substantial.

Additionally, the comprehensive technical support and ongoing product development ensure that users of Luwanhong release agent remain at the forefront of manufacturing technology. This commitment to innovation and customer support strengthens the overall value proposition for manufacturing partners.

Frequently Asked Questions

How does Luwanhong release agent improve production efficiency?

Luwanhong release agent enhances production efficiency through its quick release properties, reduced application frequency, and minimal maintenance requirements. These features lead to longer production runs, decreased downtime, and improved overall manufacturing productivity.

What makes Luwanhong release agent environmentally friendly?

The product features low VOC content, biodegradable components, and environmentally conscious manufacturing processes. It meets or exceeds global environmental regulations while maintaining superior performance characteristics.

Can Luwanhong release agent be used across different manufacturing processes?

Yes, Luwanhong release agent is highly versatile and can be effectively used in various manufacturing processes, including injection molding, compression molding, and other industrial applications. Its performance remains consistent across different substrate materials and processing conditions.

What are the long-term cost benefits of using Luwanhong release agent?

Long-term cost benefits include reduced consumption rates, extended mold life, decreased maintenance requirements, improved product quality, and reduced reject rates. These factors contribute to significant operational cost savings and a strong return on investment.