| Product Name |

Spec./Barrel |

Appearance |

Content |

PH Value |

Application Fields |

| Semi-permanent Ready-to-use Water-based Resin Fluororubber Release Agent |

25L |

Translucent liquid |

1.3-1.5% |

PH 7 |

O-rings, oil seals, petrochemical equipment sealing gaskets, valve stem seals, engineering hydraulic system step seals, glyd rings, automotive fuel lines, aerospace hydraulic hoses, engine compartment industrial thermal oil pipes, printing rubber rollers, cable sheaths, aerospace/nuclear power cable insulation layers. Sterilization equipment door sealing strips, fuel system seals, turbocharged pipes, transmission oil seals, aerospace system fuel tank seals, hydraulic system components, petrochemical pump valve seals, reactor equipment gaskets, nuclear power equipment seals in the energy sector, oil well blowout preventer components. It can also be applied to high-end non-slip rubber soles, replacing bottled mold release agents (costing dozens of rmb per bottle). A single coating enables dozens of release cycles. |

| Concentrated Water-based Rubber Release Agent |

30L,200L |

Milky white liquid |

65% |

PH 7-9.5 |

Used for mold release in rubber and plastic products to improve demolding efficiency. |

| Concentrated Water-based Rubber Release Agent |

25L,200L |

Milky white liquid |

30% |

PH 7-9 |

Used in products of reclaimed rubber, rubber floor mats, rubber tubes, EPDM (ethylene propylene diene monomer), and nitrile rubber (NBR). |

| Concentrated Water-based Rubber Release Agent |

25L,200L |

Milky white liquid |

|

PH 7 |

Used in the demolding of products of styrene-butadiene rubber (SBR), nitrile rubber (NBR), natural rubber (NR), hydrogenated nitrile rubber (HNBR), ethylene propylene monomer/ethylene propylene diene monomer (EPM/EPDM), polybutadiene rubber (BR), and isoprene rubber (PR). |

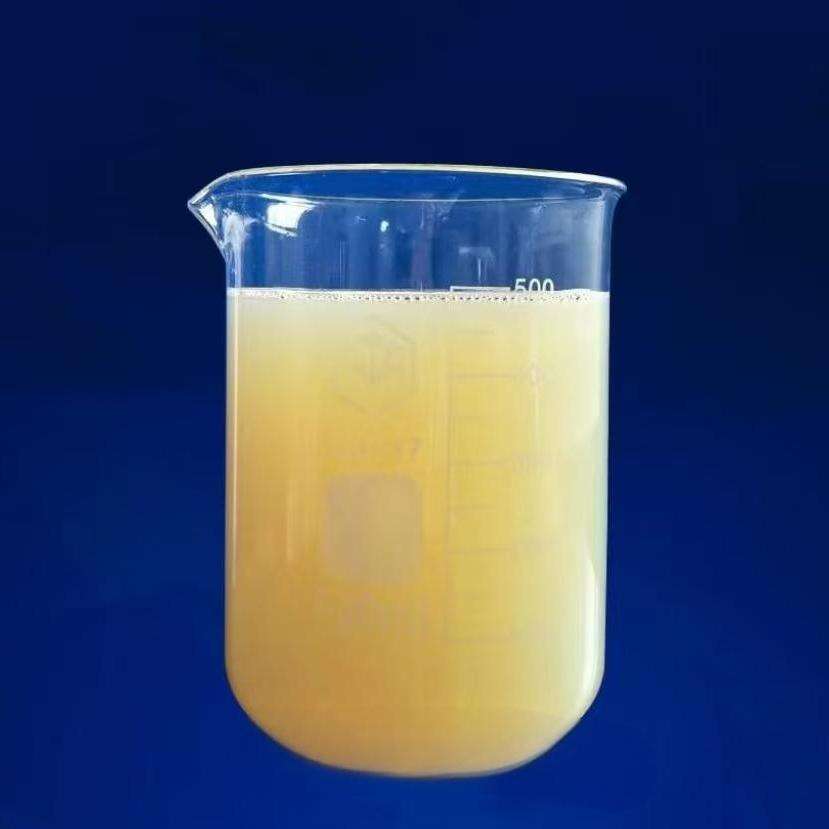

| Concentrated Water-based Fluorinated Release Agent |

20L |

Beige liquid |

10% |

PH 7 |

Fluorinated release agent (silicone-free) does not interfere with secondary processing and is suitable for specialty rubber types such as FKM (fluorocarbon rubber), ACM (acrylate rubber), NR (natural rubber), etc. It withstands temperatures up to 400°C, preventing carbonization or decomposition during high-temperature demolding, and reduces mold cleaning frequency. |

| Ready-to-use Water-based Rubber Bladder Release Agent |

30KG

200KG

1000KG

|

Milky white liquid |

3-5% |

PH 6-9 |

Used in the production of bicycle tires, motorcycle tires, and powered vehicle tires. It exhibits excellent spreading properties on the surface of inner tire, preventing clumping and oil accumulation and reducing sidewall blistering. Its superior lubrication ensures effortless tire installation, minimizing wrinkles and exposed wires. The product delivers effective mold release and a smooth surface finish. Additionally, its strong oil-retention properties help maintain and preserve the inner tire. |

| Dimethyl Silicone Oil Emulsion |

200L |

Milky white liquid |

60-66% |

PH 7-9.5 |

1. Furniture/automotive polish, extruded rubber strips, conveyor belts; 2. External release agent for rubber products; 3. Lubrication for textile machinery; 4. A. Spinning; B. Sewing thread lubrication; C. Knitwear manufacturing; D. Sewing needle lubrication, glass cloth exhaust filtration systems; 5. Lubricant for rubber/plastic gears and precision mechanical instruments under extreme high/low temperature conditions; 6. Surface treatment agent: Apply a ~10% solution or emulsion to glass, ceramics, or metal surfaces. After heat treatment at 150–300°C, a waterproof, mold-resistant and insulating film will be formed. Also applicable for waterproofing paper, leather, construction materials, and textiles;

7. Additive: Adding small amounts to coatings, rubber, wax, resins, etc., significantly improves waterproofness, gloss, oxidation resistance, and processing performance. For example, adding to paint prevents pigment floating and wrinkling while enhancing film gloss; 8. Lubricating emulsion: Used for high-speed commercial rotary printing presses and gravure printing; acts as an anti-offset agent for dry copiers and in gloss agent production. Treating spinnerets eliminates static and improves fiber drawing quality. Adding to cosmetics enhances skincare and moisturizing effects, etc.; 9. Textile raising agent: Imparts a fluffy and smooth texture to treated fabrics.

|